Nobody wins when there’s out-of-stocks (OOS). They are frustrating to both grocery retailers and consumers alike. For retailers, OOS means lost sales and eroding margins. For consumers? Well, they walk away empty-handed, and leave with a negative impression and poor shopping experience damaging the reputation you’ve built as their primary grocery store to purchase fresh items.

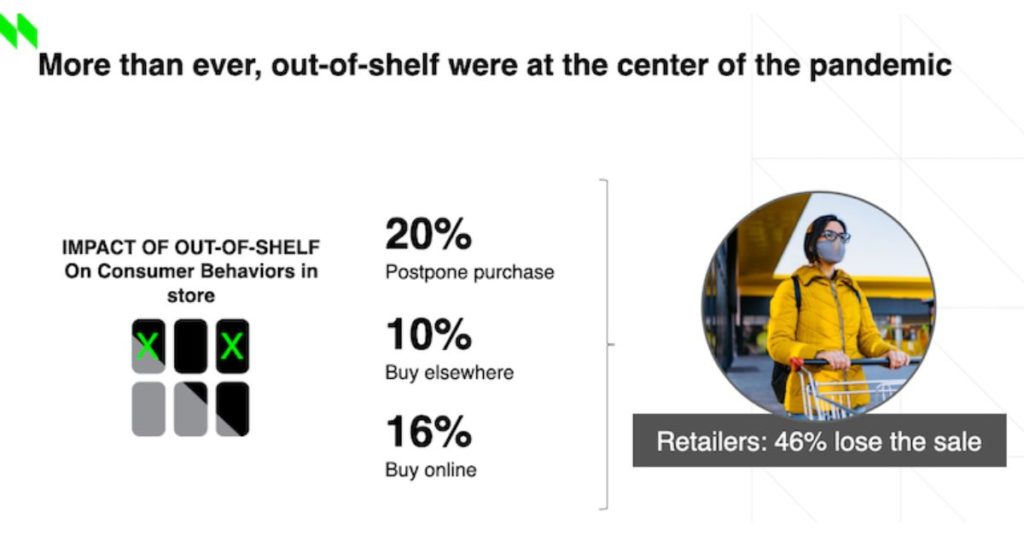

OOS is one of the most significant challenges in the fresh retail industry, and it has gotten even more attention in the pandemic as consumers seek high-demand products but are met with empty shelves.

What Causes OOS?

It all comes down to poor forecasting methodologies, error-prone safety stock calculations, replenishment issues – and of course, an added layer of complexity is created with global supply chain delays and continuing labor shortages. While the causes are complex, the negative impacts are quite simple.

Out-of-stocks cost retailers of fast-moving consumer goods (FMCG) $82 billion in missed sales last year, according to market research firm NielsenIQ in its “2021 COVID-19 Impact on Out-of-Shelf” report. That dollar figure represents 7.4% of sales not realized because of out-of-stock/out-of-shelf items.

By category, fruit experienced the most missed sales during the fourth COVID wave (July-October 2021) at over $9.84 billion, with an on-shelf availability rate (OSA) of 87.3%, NielsenIQ’s report said. That was followed by vegetables at $1.91 billion (88.7% OSA), prepared foods at $790.2 million (93.5% OSA), and processed meat at $374.4 million (93% OSA).

What’s a Grocer to do?

To ensure that in-stock positions are maintained at the highest possible level, grocers are acting fast to adopt AI-powered Fresh Retail Platforms to transform and innovate the perimeter to stay ahead of the competition. Robust fresh-centric functionality optimizes demand forecasting for all processes across fresh food retail demand forecasting, merchandising, replenishment, and compliancy and sustainability, providing a holistic, integrated, and scalable approach to driving success in fresh.

Let’s dive deeper. Take a look at these key strategies to learn how you can improve in-stock positions with a Fresh Retail Platform.

1) No more Guesswork! Data Unlocks True Visibility into Operations

Grocers have long struggled to gain better real-time visibility into their out-of-stock levels in fresh. First, they must recognize that fresh is different and require fresh-centric technology to drive any significant and lasting improvements.

Many grocery retailers use rigid technology that is traditionally built to manage non-fresh items. These systems lack the right data and analytics, flexibility, and scalability to keep up with the unique needs of fresh such as changes in consumer demand, short shelf life, unreliable supply and, changes in labor to name a few.

A Fresh Retail Platform built specifically to meet the unique challenges of fresh, removes the blindfold on operations and category/store performance. Invafresh’s Analytics is changing the way grocers look at insights and data. Powered by AI and Machine Learning, Invafresh’s Fresh Retail Platform simplifies big data to help you gain visibility into hidden opportunities, make smarter decisions and execute consumer-first fresh optimization.

- Invafresh’s intuitive dashboards provide the right data at the right time to empower grocery retailers to both stock shelves and allocate labor to meet unexpected demand surges, instantly.

- All dashboards and reports are completely interactive ‘enabling users to make well-informed, data-driven, and healthy business decisions.

- Custom drill-downs empower retailers to slice data across multiple dimensions including time, geography, department and product classifications for increased opportunities to improve performance.

- Data-driven decisions and process improvements lead to a 3% improvement of in-stock position.

2) Strengthen The Marriage of Demand and Supply

The partnership between demand and supply can be solidified by leveraging an easy-to-use Fresh Retail Platform to integrate vast amounts of data into ML forecasting algorithms that work to forecast intelligently and accurately, replenish rapidly, automate orders, plan production, manage inventory and recipes, and ensure regulatory compliance for prepared foods and perishables. Data-driven forecast engines ensure the correct amount of fresh product is ordered based on yield, sales, and, of course, demand.

Fresh-focused technology helps grocers become less dependent on long, risky and vulnerable supply of fresh food items and can adapt to rapid changes in demand and produce more locally on-demand.

Let’s say your Fresh-to-go department sees increased demand for fruit salads created in the store. You’ve increased production of the salads to meet the new demand…they are flying from shelves until you run out of a critical ingredient. Think about the missed sales caused because of one missing ingredient. What opportunities could you unlock from implementing forecast-based, automated ordering?

Sophisticated Fresh Retail Platforms take into consideration current stock, recipe-based ingredients, anticipated sales based at the daily level, store promotions, and other critical factors to generate forecasts. The result leads to 5% Fresh sales growth, 3% in-stock improvement, 3% labor efficiency, 30% food waste reduction and 100% fresher food.

By examining out-of-shelf products at a granular level, retailers now have the ability to identify and quantify lost sales, prioritize opportunities and execute on the root causes of out-of-stock products across the supply chain.

- Just-in-time model for fresh fulfillment to reduce over and under buying decisions that lead to lost margins and excess food waste.

- Forecasts of required production quantities by retail product to meet anticipated sales demand while accounting for a minimum presentation quantity and the current balance on hand.

- Capture real-time sales, shrink and production data from in-store systems to manage an accurate balance on hand throughout the day at the product level.

- Optimize merchandising with built-in powerful algorithms for live, accurate and granular forecasts from individual stores to a corporate level.

- Identify shrink at the department, store, district, and enterprise level with details on which products are the highest contributors to shrink, relative to sales.

3) Master Your Safety Stock

Safety stock is the additional quantity of a product you keep on hand to prevent an out-of-stock situation. This ensure that if there was a surge in demand, it’s less likely that you’ll run out of something before you can replenish your inventory.

Let’s say you’re a fresh retailer selling 50 sandwiches a week. While it’s reasonable to produce 50 sandwiches every week, you will want to have extra on hand to account for sudden demand spikes. For instance, you might always keep 60 sandwiches on hand. This is of course is a very basic example of safety stock.

However, many grocery retailers still manage safety stock calculations manually leading to increased OOS or overproduction resulting in increased shrink. A Fresh Retail Platform automates safety stock calculations based on accurate forecasting to protect against lost sales.

Invafresh’s Fresh Retail Platform has a safety stock setting that determines the relative probability of not being out of stock if the recommended quantity is produced. It can be configured by enterprise, store, department category and only applies when value exceeds the minimum and is built to handle any volatile sales patterns. The platform takes into consideration variety, including seasonal items to ensure shelves are always in stock and maximum shelf life is passed on to the end consumers.

4) Automate Replenishment to Avoid Under and Over Production

While intending to avoid out of stocks, the mistake many grocers often make is setting the OSA minimums for perishable products too high, using systems that are not designed for fresh operations. You guessed, it. This leads to the opposite problem of overproducing and having too much inventory (overstock).

As perishable items sit for days on grocery shelves, the likelihood of shrink increases. We all know how quickly bananas can ripen. Excess perishable items remain on shelves for days leading to a waste problem.

Invafresh’s Fresh Retail Platform generates alerts on products that are approaching an out-of-stock position so store associates can replenish products to ensure adequate on-shelf availability. Grocers can track, measure and alert on out of stocks of fresh retail items produced in-store after and before they happen to retain high sales opportunities while aligning to just-in-time production that reduces chances of excess shrink.